Here we can see a demonstration of the struggle users have to face when eating Pringles. Users with larger hands struggle to reach inside the container or dump the chips out. This very issue was highlighted in the 2022 Pringles Super Bowl Ad that is feature below.

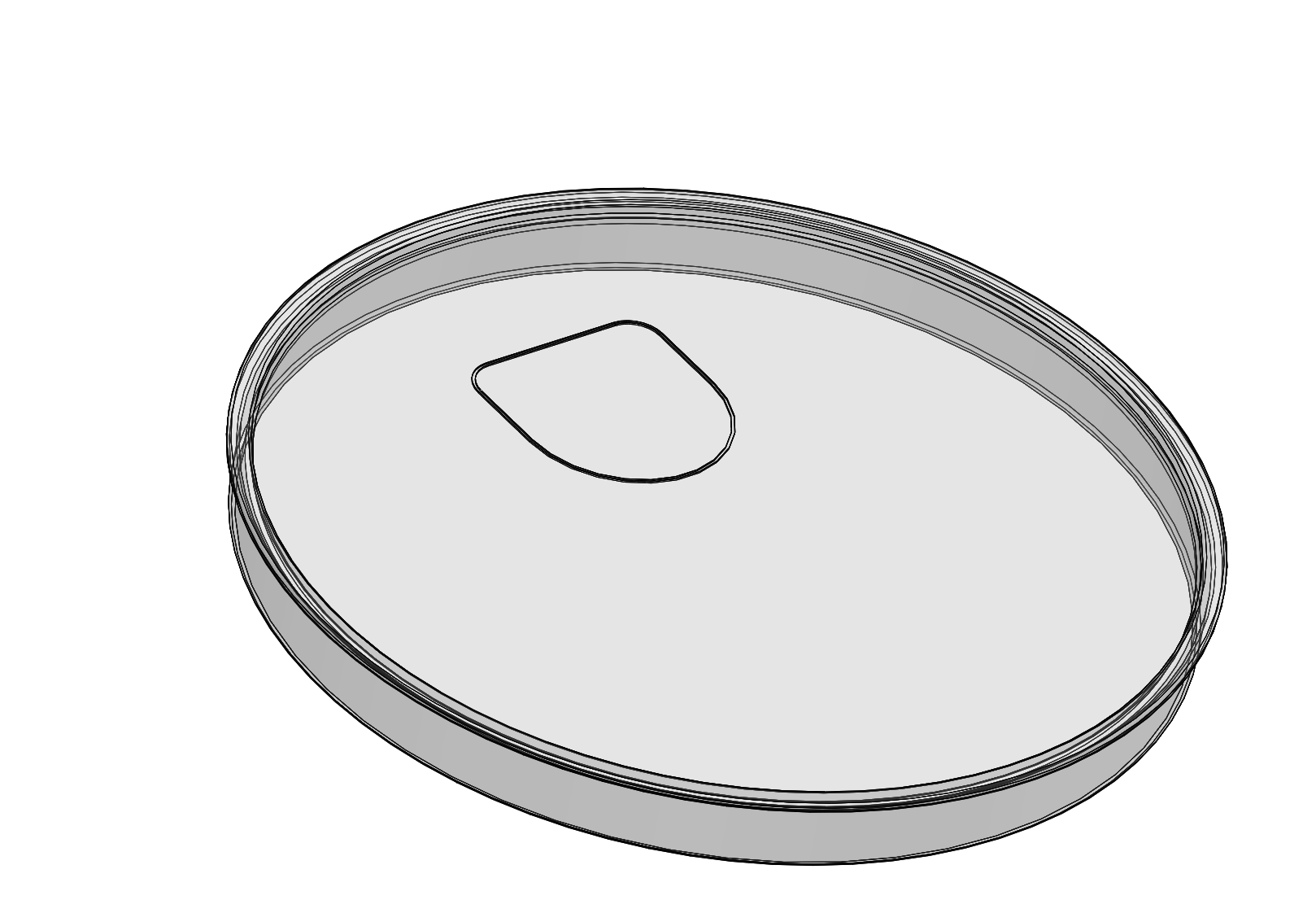

Communicating with the team about how we will execute our plan. We use empty Pringles containers and tape to make low-fidelity prototypes that we were able to test with users.

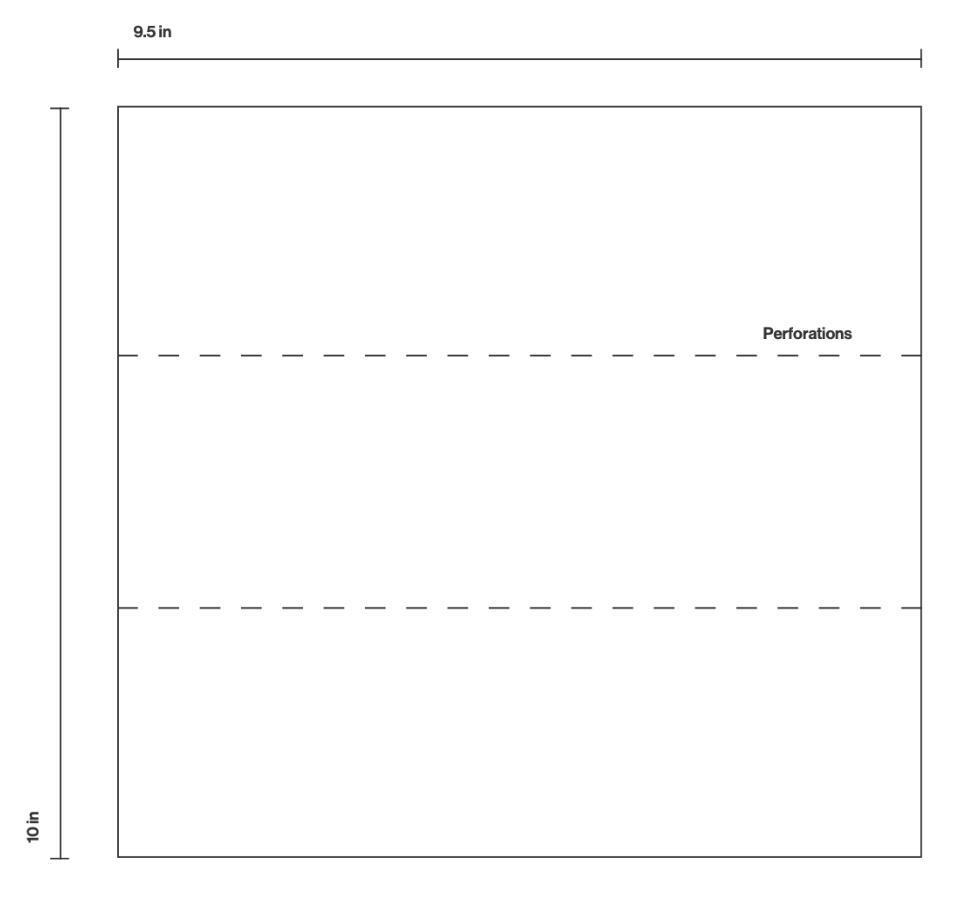

In order to place graphics and branding on the packaging we utilized spray adhesive to glue on a pre-perforated sleeve that had been designed specifically for this prototype.To ensure the design was rigid enough to withstand shipping to stores we used a heavier weight paper.

Hannah Stites, Dylan Bowden, Katie Foder (left to right)